1

/

of

5

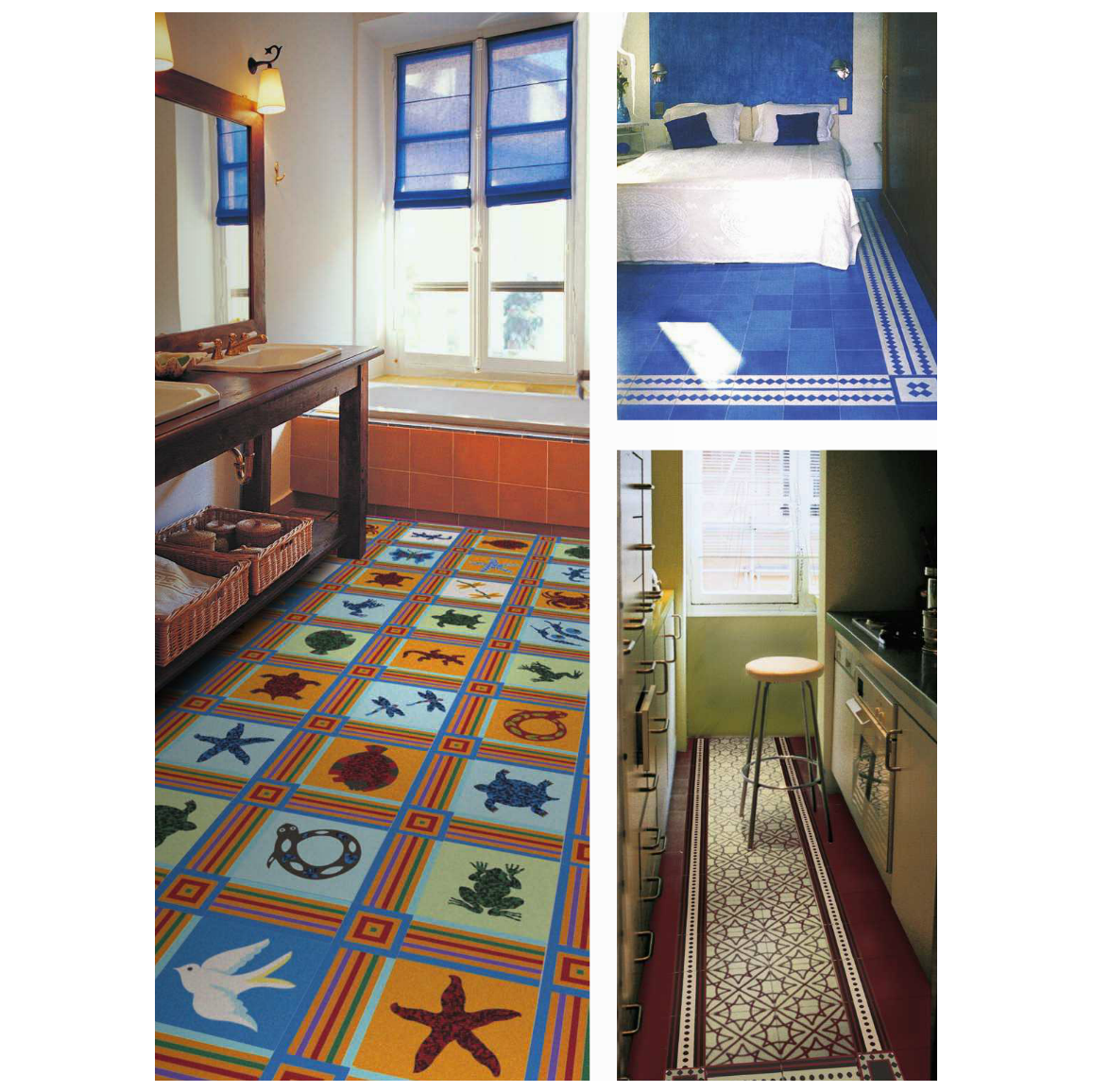

White, Red and Grey Ridge Corner Carocim Tile (8" x 8") (Individual Tile)

White, Red and Grey Ridge Corner Carocim Tile (8" x 8") (Individual Tile)

SKU:689110

Regular price

$10.00 USD

Regular price

Sale price

$10.00 USD

Unit price

/

per

Shipping calculated at checkout.

Low stock: 1 left

Couldn't load pickup availability

Share

*Please note that we are not offering direct shipping for artisan tile via the Maison Midi website. For checkout please select "In Store Pick Up" as delivery method. Contact maisonmidi@amrag.com for LA local delivery quotes and options or please add a note at checkout. Tile orders may take up to 5 business days to process.

Please click this link and take a glimpse into how Carocim’s stunning artisan crafted tiles are made, one by one.

Carocim stay true to history. Each tile is artisan made, using the same classic hydraulic presses that were first introduced in France in 1850. In 1950, the last French manufacturer of cement tiles closed it doors and what little of the almost extinct process moved to Morocco, under the French protectorate. The stunning and lively floors with detailed colored motifs were almost lost in history forever. Christian Berthéas, trained as a Building Architect, rediscovered the beauty and importance of traditional cement tiles while on a trip to Morocco. Upon his discovery, Berthéas founded the company Carocim in 1986. His goal was to create beautiful cement tiles in the same classic manner as generations before him. “I believed in the renewal of this material and I started my business in 1986. Today, we work exclusively with two Moroccan manufacturers, using artisanal techniques.” One layer of powdered marble and siliceous sand coated with white cement is poured into a mold. Then, a divider, which looks somewhat like a brass stencil, is put in place, and the colored pigments for the motifs are injected. Then each tile is filled in with mortar, compressed with a hydraulic press, taken out of the mold, bathed and dried. At least 20 different processes are needed to make a cement tile.8 x 8 inch square

0.63 inch tile thickness

Details: Tiles are artisan made wall and floor coverings with a cement binder, obtained by compression.

Tile consists of two layers: Top layer known as the wear and tear layer whose visible surface is called the “fair side.” made up of marble and siliceous sand, coated with white cement mixed with coloured pigments (ochres and metal oxides). Base known as the sole “laying side.” the sole is made up of a mixture of sand and cement.

Each tile weighs approximately 3 pounds / sold individually

*Each tile is hand crafted, one at a time. There may be a slight deviation in final color and size, which adds to the character and charm of each tile.

How to calculate Carocim Tiles:

One square foot is equal to 144” (1 sq. ft = 12” x 12”)

Carocim tile is 8” x 8” = 64”)

Please take the square footage of the area you wish to tile and multiply that number by 144 inches. Take the total square inches and divide it into 64 inches (the square inches of the Carocim tile) to get the amount of tiles desired. We recommend that you round up and add an extra 10% for breakage.

*These calculations do not include grouting.

Example: 1. Your area is 58 square feet. Multiply by 144” = 8,352 square inches. 2. Take 8,352 square inches and divide by 64” = 130.5 tiles. 3. Round up to 131 tiles. 4. Add 10% for breakage (131 x 1.1 = 144 tiles)

Please click this link and take a glimpse into how Carocim’s stunning artisan crafted tiles are made, one by one.

Carocim stay true to history. Each tile is artisan made, using the same classic hydraulic presses that were first introduced in France in 1850. In 1950, the last French manufacturer of cement tiles closed it doors and what little of the almost extinct process moved to Morocco, under the French protectorate. The stunning and lively floors with detailed colored motifs were almost lost in history forever. Christian Berthéas, trained as a Building Architect, rediscovered the beauty and importance of traditional cement tiles while on a trip to Morocco. Upon his discovery, Berthéas founded the company Carocim in 1986. His goal was to create beautiful cement tiles in the same classic manner as generations before him. “I believed in the renewal of this material and I started my business in 1986. Today, we work exclusively with two Moroccan manufacturers, using artisanal techniques.” One layer of powdered marble and siliceous sand coated with white cement is poured into a mold. Then, a divider, which looks somewhat like a brass stencil, is put in place, and the colored pigments for the motifs are injected. Then each tile is filled in with mortar, compressed with a hydraulic press, taken out of the mold, bathed and dried. At least 20 different processes are needed to make a cement tile.

Information

DimensionsDetails:

Tile consists of two layers:

*These calculations do not include grouting.

Example: 1. Your area is 58 square feet. Multiply by 144” = 8,352 square inches. 2. Take 8,352 square inches and divide by 64” = 130.5 tiles. 3. Round up to 131 tiles. 4. Add 10% for breakage (131 x 1.1 = 144 tiles)